Composite

Elevated Tanks

A Landmark Invention

Best-in-class Design and Function

Landmark invented the Composite Elevated Tank (CET) and led the development of national standards that support the product. We have designed and constructed more CETs than all other companies combined.

The CETs advanced design provides:

- Modern aesthetic

- Robust design and most efficient use of materials

- Lowest capital and lifecycle costs

- Multi-use pedestal that drives further efficiencies

The CET is the lowest-lifecycle cost tank design for elevated water storage from 500,000 to 5,000,000 gallons.

Project-Specific Tank Budgets

Landmark offers fully customized project budget estimates for all major tank styles.

- Tailored to your project specifications

- Fully inclusive of all project costs

- Regionally adjusted for labor, materials, and current market conditions

We provide the most accurate, and detailed budgets in the industry.

Lifecycle Analysis

To select the best solution, Landmark provides a present value lifecycle cost analysis which combines a detailed assessment of:

- Capital cost

- Ongoing maintenance and repair costs

- Other significant project specific costs

Impact of long-term inflation and interest are included to provide the full and accurate cost over the life of the asset – presented in today’s dollars.

The Landmark Difference

As the CET leader, Landmark maintains the highest standards.

Attention to Detail

Beyond their function as an essential element in water system infrastructure, Composite Elevated Tanks have another role. Community identity is often associated with a highly visible elevated tank, so we pay attention to the details.

We go above and beyond, partnering with customers to evaluate needs and provide input on enhanced safety, quality, functional, and aesthetic features to ensure best value.

With Landmark’s advanced concrete, steel tank and coatings processes, we set and deliver the highest standards of quality and appearance.

Engineering Expertise

Landmark has a dedicated team with the capabilities to solve the most challenging engineering problems.

We have designed and constructed the largest and tallest CET structures subjected to extreme climate, high wind, and high seismic environments.

And we have enhanced many features for special operating and aesthetic considerations.

Industry Leading Concrete Process

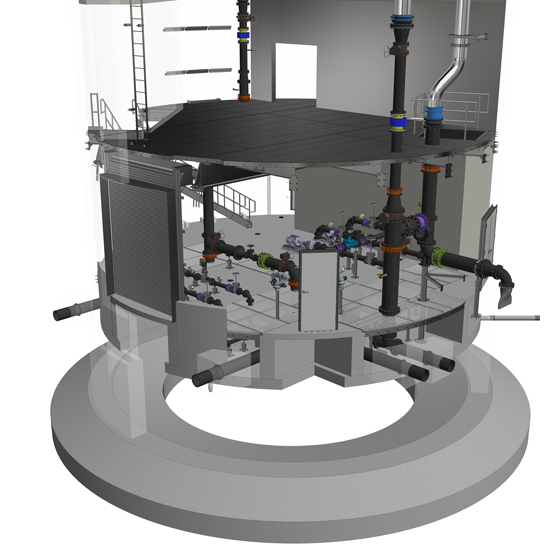

The reinforced concrete pedestal differentiates the Composite Elevated Tank. This element must be designed and constructed precisely to satisfy critical structural, durability, and architectural requirements.

We have the experience of over 15,000 separate wall segment placements and have refined methods and controls to ensure the highest structural, durability and aesthetic standards are attained.

Our concrete specialists are experts in managing mix designs, the critical impact of environmental conditions on the placement process, rigorous quality control procedures, and the involvement of supplier partners.

Highest Quality Steel Tank

Landmark has made large investments in fabrication and construction equipment to produce the largest steel plate components in the industry. Benefits include reduced weld seams, efficient installation, and improved quality of coating systems.

We leverage a highly skilled steel tank installation workforce, proven processes, and stringent quality control including non-destructive testing of weld joints.

Landmark is the company of choice for Composite Elevated Tanks

Speak to an expert about your next project.