by Adam Reed | Oct 18, 2023

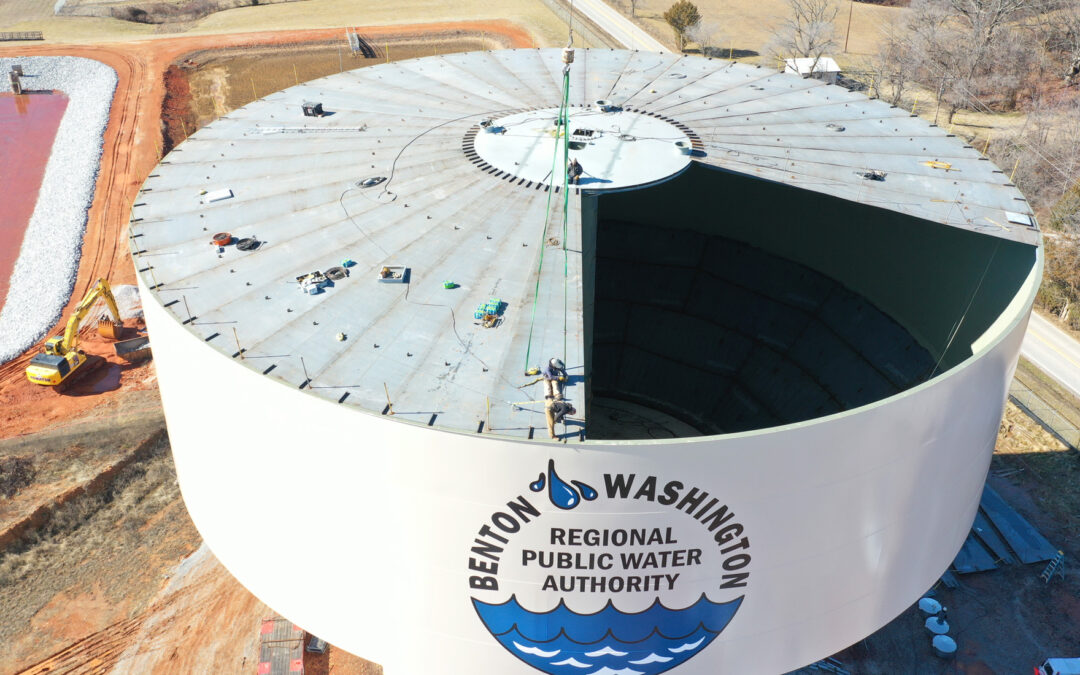

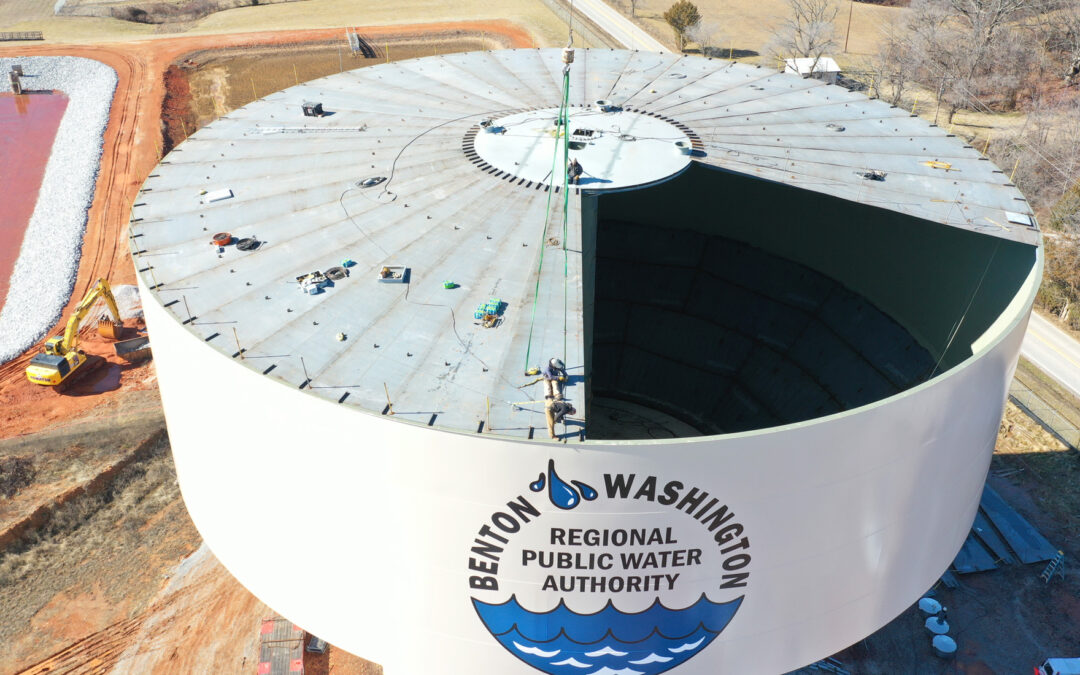

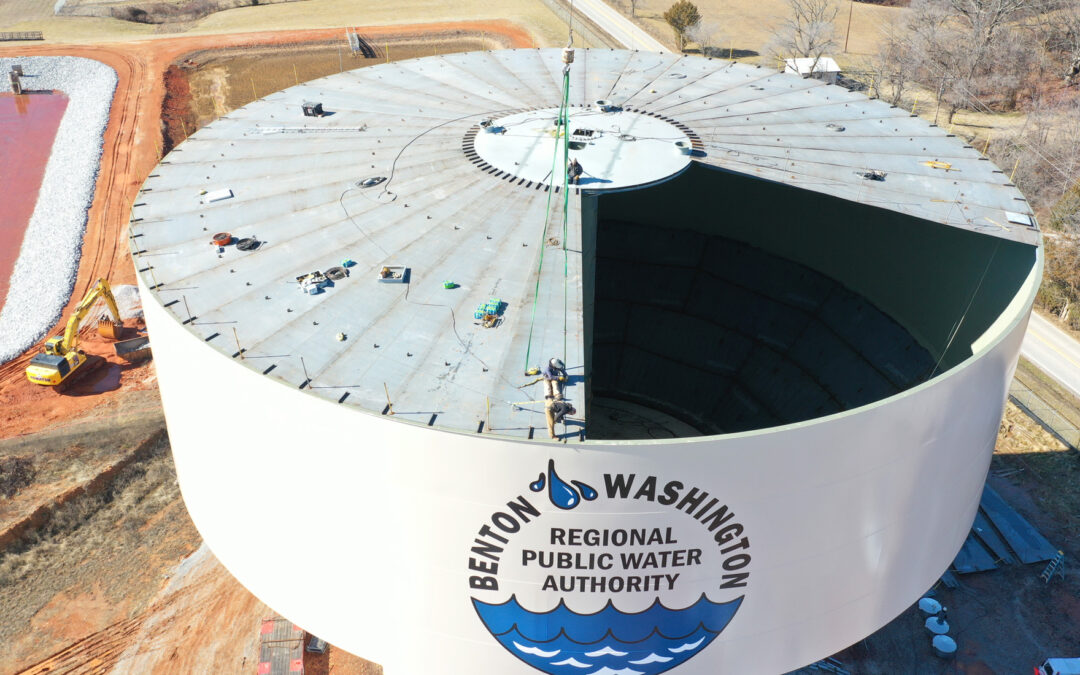

The project site and soil conditions were unsuitable to support the concrete foundation of the 4.0 MG CET. Vibratory stone columns were utilized to improve the soil structure, and a secondary construction entrance was constructed to support the large volume of truck...

by Adam Reed | Oct 3, 2023

The Region required complex deliverables and plans to prioritize capital expenditures on 34 tanks. Landmark developed a detailed Annual Risk Based Capital Plan and 20-year Infrastructure Improvement Program (IIP) for the Region. Operational Highlights: Landmark has...

by Adam Reed | Oct 3, 2023

The Big Spring refinery operated by Delek US (formerly Alon USA) has a crude oil throughput capacity of 70,000 barrels per day. Alon required an Isobutane storage sphere to be erected by Landmark. The project required precise fabrication tolerances and welding...

by Adam Reed | Aug 8, 2023

Efficiently transporting viscous oil from Alberta’s tar sands region requires dilution and solids removal. CNRL required the addition of a froth tank near an extraction zone, which is designed to heat diluted bitumen, causing the viscosity to drop enough to allow...

by Adam Reed | Aug 8, 2023

The OPG Aguasabon Generating Station required replacement of the aging 1940’s surge tank infrastructure located on the penstock that feeds the stations turbines. The project followed an expedited schedule and faced design and engineering challenges as well as...